Currently Digital Service Providers (DSPs) traditional field service operations involve more human effort such as manual order entry, multiple follow-up activities while creating truck roll appointments. Since the truck roll appointments are created manually and without thorough assessment and validation, results in many non-productive dispatches. For example, multiple truck rolls for the same customer account for different types of service issues can incur an unnecessary cost to DSPs.

Current state of DSPs’ field service operations

On average, 40% of the network tickets call for service truck roll dispatches, out of which 25% are found to be non-productive. The real business problem with the traditional field service approach is unavailability of efficient processes and tools to identify non-value added (NVA) service truck rolls and its associated operational expenditure.

Traditional service truck roll dispatch process involves the following steps

- Customer reports various issue using self-service portal, mobile app, IVR to customer care

- Customer Service Representative (CSR) follows a standard troubleshooting guide

- CSR creates an appointment for a site visit to resolve the problem

- Service truck roll (On-site visit): Field technician visits customer location to fix the issue

In many cases, after visiting customer location, field service technician finds that a site visit was not really required to fix the problem. These are service calls that result in ‘no issues found’ or ‘problem already resolved’ – These non-productive dispatches cost millions of dollars to DSPs.

Proven strategy for DSPs to address service truck roll inefficiency issues

Three major steps are followed to address service truck roll inefficiency issues, as follows

Collecting data from multiple sources

— Call center logs comprising of transaction and work order related logs

— CRM logs consist of customer and work order related data

— Fault/ticket handling data such as historical records with impact, urgency, service impacted parameters and cases that requires multiple visits

— Performance metrics such as device health statistics, traffic & bandwidth details

— Network events & alarm details, device/node info & location details

— Device log info such as modem & controller info (common issues with customers)

Additional inputs to augment decision making capability

— By leveraging CSR’s and SME’s inputs to augment decision making

— Performing root cause analysis of past ticket data

— Enhanced data handling capability by using big data platform

Apply analytics to identify the major NVA truck rolls

— By applying data analytics process or methods like statistical data analysis to identify the major NVA truck rolls

Using Pareto principle and Correlation analysis, the top 20% causes that leads to 80% NVA truck rolls could be found and optimized. Applying these steps results in identification of the major causes for NVA truck rolls. DSPs can proactively filter out the identified non-productive dispatches to reduce field service operation cost.

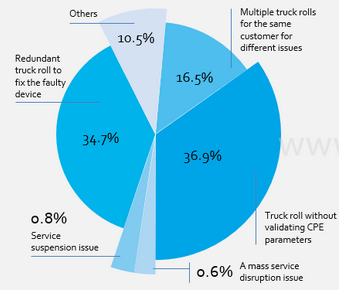

Sample non-value-added reasons identified during analysis phase

Applying statistical data analysis, a leading DSP in Europe has identified the top five operational inefficiencies is shown in the following figure.

Truck roll without validating CPE parameters: CSR sends truck roll without pre-validating the CPE threshold parameters against the recommended guideline like

— CPE with fluctuating SNR level

— CPE Tx/Rx out-of-range threshold level etc.

Redundant truck roll to fix the faulty device: Device upgrade (hardware swap) work order is in progress to resolve the existing issue. CSR sends another truck roll without checking the device upgrade or swap appointment.

Multiple truck rolls for the same customer for different issues: Often multiple work orders are raised for the same customer account for different types of services without validation, for which the CSR sends multiple truck rolls to fix it.

Service suspension issue: Truck roll for customer site whose account is in “suspended’’ state. CSR raises work order without validating the account is active or not.

A mass service disruption issue: In the case of known service outage in a specific region, different teams work together to resolve the issue. CSR sends truck roll without validating mass service disruption details of the reported issue.

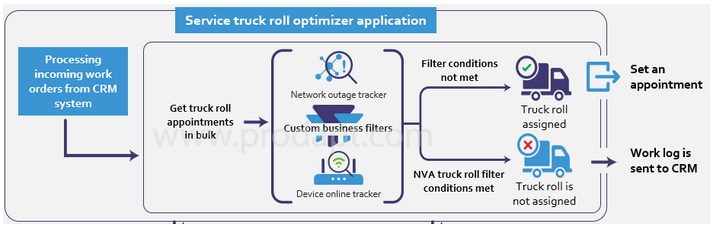

Implementing automated service truck roll optimizer

Recommending DSPs to build a customized service truck roll optimizer application encompassing three major components namely, custom business filters for the identified top five to ten NVA truck roll issues, Device Online Tracker module and Network Outage Tracker module.

Integrate service truck roll optimizer application with CRM system for real-time optimization. Service truck roll optimizer automates work order updates in system, so the time taken is lesser than manual process.

Service truck roll optimizer application filters the NVA truck rolls, and the work logs are shared with CRM system. Any work order that doesn’t meet the business filter criteria will only result in a truck roll.

The service truck roll optimizer has intuitive UI which shows the consolidated view of total NVA truck roll cases found against each business filter conditions.

Key elements in service truck roll optimizer

Device online tracker

Tracker module gets all customer device online status information using external API calls to downstream service assurance systems. Also, it fetches real-time health information status from CPE devices which enables service truck roll optimizer to identify incoming work order as NVA truck roll or not.

Network outage tracker

The outage tracker module processes mass network outage issues from central alarm manager system in real time and after processing, converts it into an understandable format for service truck roll optimizer. It enables service truck roll optimizer to identify incoming work order as NVA truck roll or not. For (e.g.) for “A mass service disruption issue.”

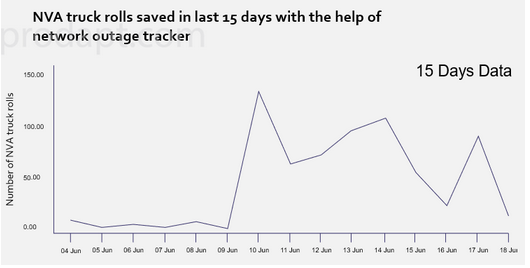

NVA truck rolls saved for a 15-day period with the help of network outage tracker

Key benefits achieved by a leading DSP in Europe

Applying statistical analysis techniques and building service truck roll optimizer described in this insight resulted in the following benefits, 27.4% percentage of NVA truck roll saved with increased first-time fix rate, shorter arrival times, and more engaged technicians

Field service operation cost reduced by 20% through eliminating NVA truck rolls leading to 2.589 million Euros savings per annum

Authors:

Selvakumar B – Assistant Vice President, Prodapt Solutions

Dineshkumar KS – Technical Lead, Prodapt Solutions

Philip Richard D – Project Manager – Delivery, Prodapt Solutions

Mogan A.B. – Manager, Strategic Insights, Prodapt Solutions